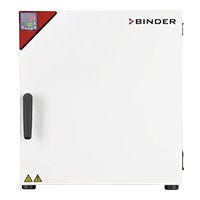

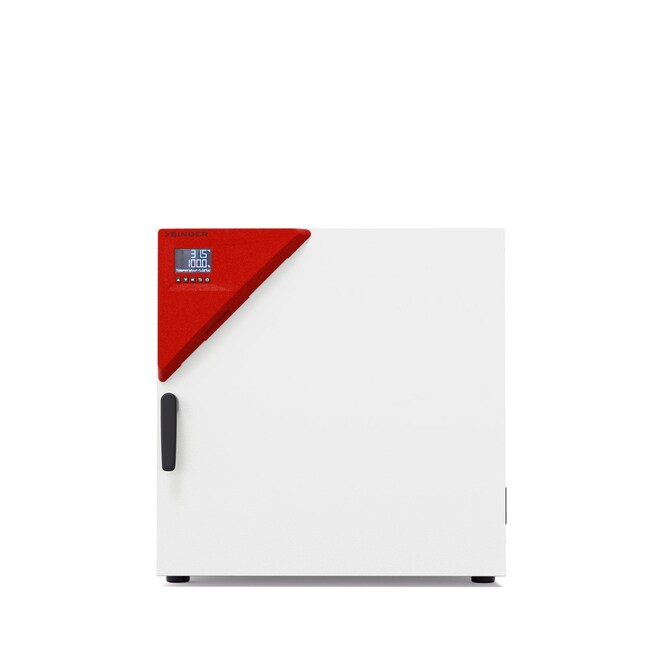

Heating and Drying Ovens

Heating and drying ovens are used for simultaneously heating and drying samples. Features include gravity or mechanical (forced air) convection, capacity, achievable temperature, programmability, and scheduled on/off cycles. Applications include drying, baking, aging tests, glassware drying, dry sterilization, and processing electronics.

Useful Links

Save Now - Exclusive Deals

Product Code 15953052

Product Code 10291870

Product Code 10349839

Product Code 15805911

Complete Your Order - Great Deals

Must Have

Product Code 12861503

Product Code 10775182

FAQ

A laboratory heating or drying oven is designed to provide controlled, uniform temperatures for applications such as drying glassware, removing moisture from samples, sterilizing instruments, and conducting thermal testing. They are widely used in research, quality control, and industrial laboratories.

Natural convection ovens rely on rising hot air to circulate heat, which is ideal for gentle drying and reduced sample disturbance. Forced convection ovens use a built-in fan to provide faster, more uniform heating, making them better suited for higher throughput or when consistent drying conditions are critical.

Important factors include temperature range and stability, chamber size, safety features (such as over-temperature protection), air circulation (natural vs. forced convection), and whether vacuum or inert gas operation is needed. Accessories like additional shelves, data logging, or inert gas kits can also improve usability.