Monoclonal Antibody Production

Discovery and Development

Discovery and Development

mAbs discovery and development necessitate a series of intricate procedures aimed at achieving consistent and reproducible outcomes. Employing a Chinese Hamster Ovary (CHO) platform enables efficient and straightforward selection and scale-up of clones for manufacturing. Explore our range of cell line development kits, optimized media, supplements, feeds, essential equipment, and other tools that expedite the process and minimize development time.

Optimization and Scale Up

Optimization and Scale Up

Efficient conversion from pilot to process scale and smooth technology transfer demand meticulous organization, effective communication, and thorough documentation. Choose appropriate media, single-use products, and instruments that adhere to stringent quality standards, ensuring high performance, scalability, enhanced speed, flexibility, and reduced capital requirements.

Clarification and Purification

Clarification and Purification

Optimizing the downstream steps in monoclonal antibody (mAb) processing is paramount for guaranteeing product quality, yield, and sterility. Explore our comprehensive range of products designed to enhance separation efficiency and filtrate quality, all while minimizing biomanufacturing costs.

Protein Characterisation and Analysis

Protein Characterisation and Analysis

Achieving optimal monoclonal antibody (mAb) production requires efficient protein characterization and analysis. Explore our advanced solutions for precise protein identification, quantification, structural analysis, post-translational modification profiling, and stability assessment.

Fill and Finish

Fill and Finish

To meet the requirements of fill and finish processes for mAb production, products must be prepared in an ISO Class 5 environment and comply with sterile, pyrogen-free, and particulate-free standards (USP71, USP85, USP758). Additionally, they should be validated for storage of frozen or lyophilized drug product and compatibility with the protein and excipients in the final formulation. Explore our product choices for mAb fill and finish, including RTF vials, chemicals, buffers, production water, and environmental control products.

Single-use Solutions

Single-use Solutions

Our innovative single-use technologies accelerate biological manufacturing, enhancing flexibility and efficiency in upstream and downstream workflows. Achieve consistent and scalable processes with our industry-leading standard single use products.

View relevant resources

Related Resources

Eppendorf Centrifuges for mAB Discovery Workflow

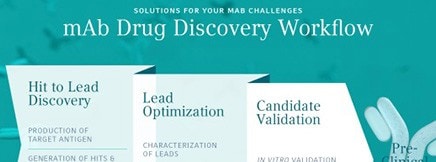

Antibody development poses challenges, with time and budget constraints. Optimizing each production step, from transfection to scale-up, is crucial. Eppendorf offers solutions, expertise, and tools to enhance antibody yield and quality, ensuring a competitive edge.

The Rise of Monoclonal Antibodies as Blockbuster Drugs

In 2018, seven out of the top ten best-selling drugs were monoclonal antibodies, including AbbVie's highly successful therapy Humira (adalimumab) for immune disorders. Discover the function, challenges, and future of mAbs in our lab reporter article.

All you need to know about

Monoclonal Antibody Production

Monoclonal antibodies (mAbs) have revolutionized medicine since their inception in 1975 by Köhler and Milstein. With 162 approved therapies targeting various diseases, including cancer and infections, mAbs have become highly effective and top-selling drugs. They are also being investigated for autoimmune, neurodegenerative, and cardiovascular conditions due to their versatility and specificity. However, the development and production of mAbs pose challenges, requiring significant time, resources, and complex manufacturing operations. The Fisher Scientific channel offers advanced solutions to streamline the development process and ensure cost-effective antibody production for all steps from cell line development to final fill.

Find out more

Frequently Asked Questions

What Is a Monoclonal Antibody?

Monoclonal antibodies are laboratory-produced molecules engineered to serve as substitute antibodies in fighting disease. They mimic the body's natural immune response and target foreign agents.

What Are the Challenges of mAbs Development?

Challenges in mAbs development include time and resource requirements, labor-intensive processes from identifying suitable target antigens to generating high-affinity antibodies, stringent manufacturing control and optimization, and high costs associated with production, research, and development.

What Is the Most Used Cell Platform for mAb Development?

The most widely used cell platform for mAb development is the Chinese Hamster Ovary (CHO) cell line. CHO cells have become the preferred host for mAb production due to their genetic stability, high protein expression levels, ability to perform post-translational modifications similar to human cells, scalability, and regulatory approval for commercial production. The CHO cell line has a long history of safe use in biopharmaceutical manufacturing and offers a robust infrastructure with established protocols and knowledge base, making it an efficient and reliable platform for mAb development.

Need More Information or Help?

Contact us

Talk to a Sales Representative

If you have questions regarding our products, services and offers, or should you require technical assistance, please request a call-back to be contacted by our Specialist Sales Representative.

Talk to a Safety Specialist

Contact us today to talk about any safety issues or to advise on product selection.

Fisher Scientific Biotech News

Join our mailing list and receive updates on new product announcements, special promotions, sales, and more.

.jpeg-650.jpg)

.jpeg-650.jpg)